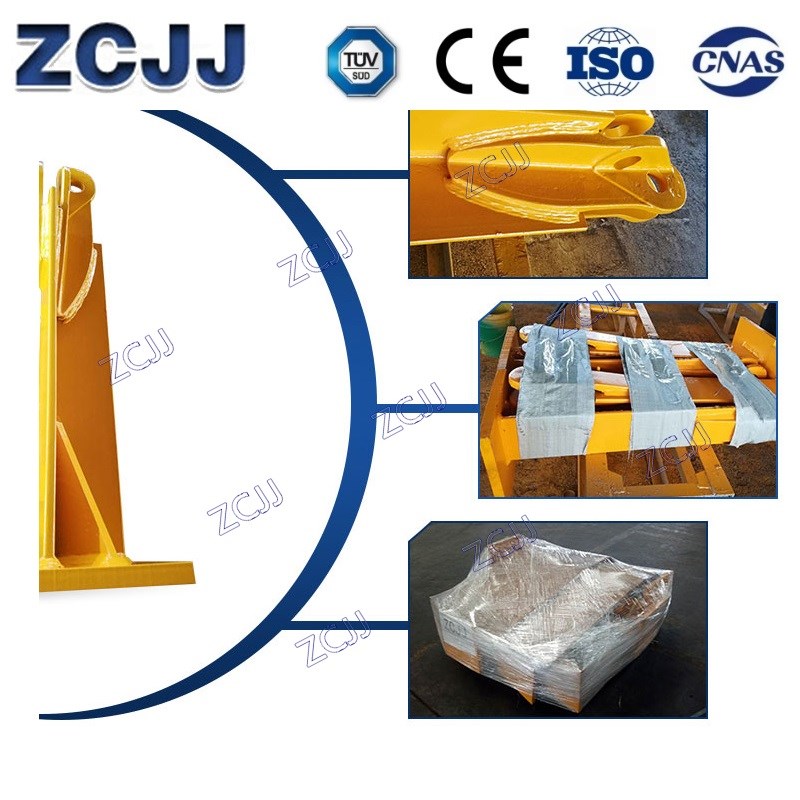

R12C Bases Fixing Angle Tower Crane

- ZCJJ

- China

- 3days

- 20sets

Senegal Tower Crane, Gambia Tower Crane,

Products Specification

Type , Model: R12C Bases Fixing Angle Tower Crane

Size: 1.2M

Use for : S24A1 S24D1 S24D2 mast section , 1.2m L type mast

Materials: Q345B

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

R12C Bases Fixing Angle Tower Crane

Tower Crane Knowledge sharing:

How to operate to ensure the normal operation of heavy crane

How should heavy tower cranes be operated under special circumstances to ensure normal operation of heavy tower cranes

1. Go ahead and fix and attach after tower crane

When the mobile range of the tower crane cannot cover the whole length of the building, and the height of the building exceeds the height limit for the tower crane to walk freely, the tower crane can adopt the construction method of going first and then fixing and attaching.

For this reason, in addition to laying track foundation along the building in accordance with the conventional practice, should also be in the tower crane construction later fixed adhesion position, pre-built concrete foundation under the track.

R12C Bases Fixing Angle Tower Crane

In order to enhance the bearing capacity of the original track foundation, to prevent uneven settlement.

2. Fixed construction first, then walk and anchor

The tower crane first stands on the slope for foundation construction. After the foundation pit is backfilled, the high-rise construction needs to be close to the building and anchored with the building.

For this reason, partial concrete track foundation can be laid first, and then the concrete track foundation can be extended on the compacted foundation, so as to meet the needs of anchoring after the tower crane moves.

Attach first, then remove when walking

For the L or U shaped buildings, the attached tower crane can meet the requirements of hoisting construction, but after the completion of the structure, limited to the structure size of the tower crane can not be removed in situ.

To this end, a section of track foundation needs to be laid so that the tower crane can exit from the narrow space along the track, so that the tower can be dropped and dismantled by the usual technology and auxiliary machinery.

R12C Bases Fixing Angle Tower Crane

4. Climb inside first, then attach and fix

For high-rise buildings with complex shapes, the lower part shall be hoisted by internal climbing tower cranes first, then the upper or super high buildings shall be constructed by anchoring devices, and then the market or super high buildings shall be constructed by anchoring devices.

For this reason, the most suitable location should be selected for the inner tower crane and the concrete foundation should be built. The upper part of the inner climbing tower crane should be equipped with hydraulic jacking jacket.

Install the tower crane on the floor

In the main construction of high-rise buildings, it is often necessary to install the attached tower crane on the roof of the basement or the skirt house to carry out the construction of the tower part.

Therefore, the floor structure where the tower crane is installed should be checked and strengthened, and support should be added under the floor (at least two consecutive floors) to ensure safety.

R12C Bases Fixing Angle Tower Crane