Topkit 10Ton Tower Crane Hammer Head

- ZCJJ

- China

- 30DAYS

- 5 units

The boom section usually has 4m, 5m or 10m sections. Taking the 50m lifting boom as an example, its maximum unit mass is only about 1/5 of the total amount of lifting boom. Compared with the whole lifting, the lifting equipment required by the disassembling and assembling of the boom in air section by section is greatly reduced, which not only saves the cost of disassembling and assembling, but also is safer and faster.

Description Specification

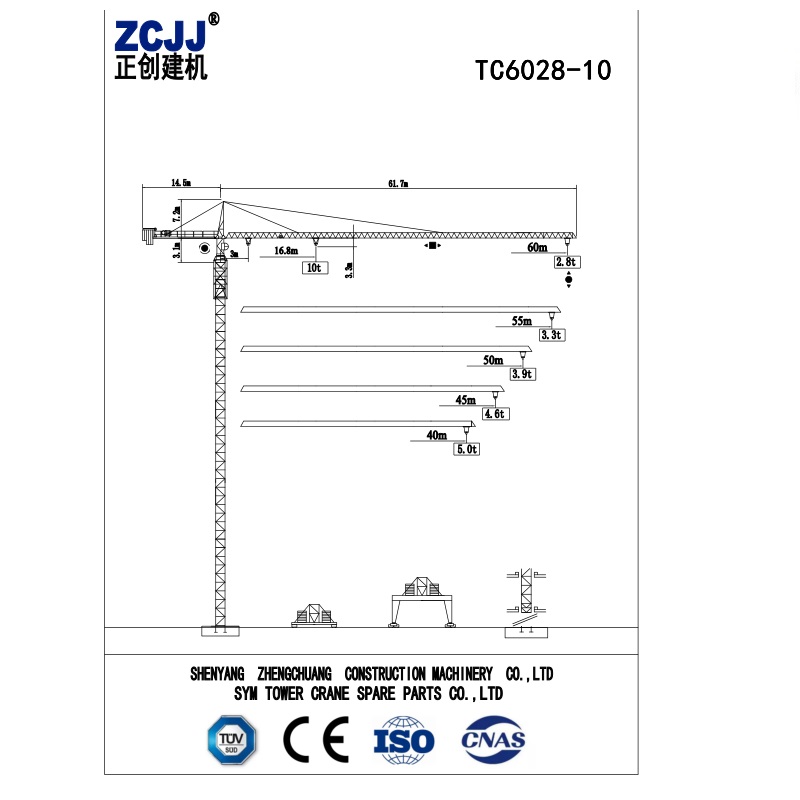

10Ton Hammer Head Topkit Tower Crane ,

Model: TC6028 , TC6015

Jib length: 60m

Max load: 10Ton

Tip load: 2.8Ton or 1.5Ton

Mast type: 2m , L68B2 Mast Section,

2m , L68A1 Mast Section , AND 1.6m , L46A1 Mast Section

Type, Stationary , Inter Climbing , Travelling.

10Ton Hammer Head Topkit Tower Crane ,

Tower Crane Knowledge sharing:

Maintenance and repair knowledge of tower crane motor

Maintenance and repair knowledge of tower crane motor

1) The motor should be kept clean during use. There should be no dust, fibers, etc. on the brush grip device and the collector's ring. The inlet and outlet should not be hindered by dust, fibers, etc.. No debris, rain or other conductive liquid is allowed to enter the motor.

2) When the motor protection device continues to act, it should be determined whether the fault comes from the motor or the overload or the protection device is too low to eliminate the fault before it can continue to operate.

10Ton Hammer Head Topkit Tower Crane ,

3) The motor should be well lubricated during the operation of the motor. Generally, the motor should be supplemented and replaced for about 5,000 hours. When it is found that overheated or the grease has deteriorated during operation, the lubricating grease should be replaced in time.

When the lubrication is changed, the old lubricating grease should be removed. The oil of the shaft and bearing is washed with gasoline, and the grease is then filled with 2/3 of the cavity between the inner and outer rings of the bearing in accordance with the lubricating grease number specified in the Tower Hang Lubrication Table. The sealed bearing does not need to be replaced during the life period. Grease.

10Ton Hammer Head Topkit Tower Crane ,

4) The insulation of the motor housing shall be detected to be greater than 0.5 MΩ or more. Motor wiring cable shall be free from damage.

5) Check whether the motor fastening bolt is loose and tighten it if necessary.

Knowledge of electrical system maintenance and maintenance of tower crane

Knowledge of electrical system maintenance and maintenance of tower crane

1) Always check all wires and cables for damage, and bandage or replace damaged parts in a timely manner.

2) When the motor is overheated, it must be parked in time. After troubleshooting, it must continue to operate. The motor bearing must be lubricated well.

3) All control boxes, distribution boxes, etc. must be kept clean and dust off electrical equipment in a timely manner.

4) The contact of the trip switch on each safety device must be reliable, and the contact arc pit should be polished in time.

10Ton Hammer Head Topkit Tower Crane ,

5) The protective ground resistance should be measured twice a year to ensure that it does not exceed 4 Ω.