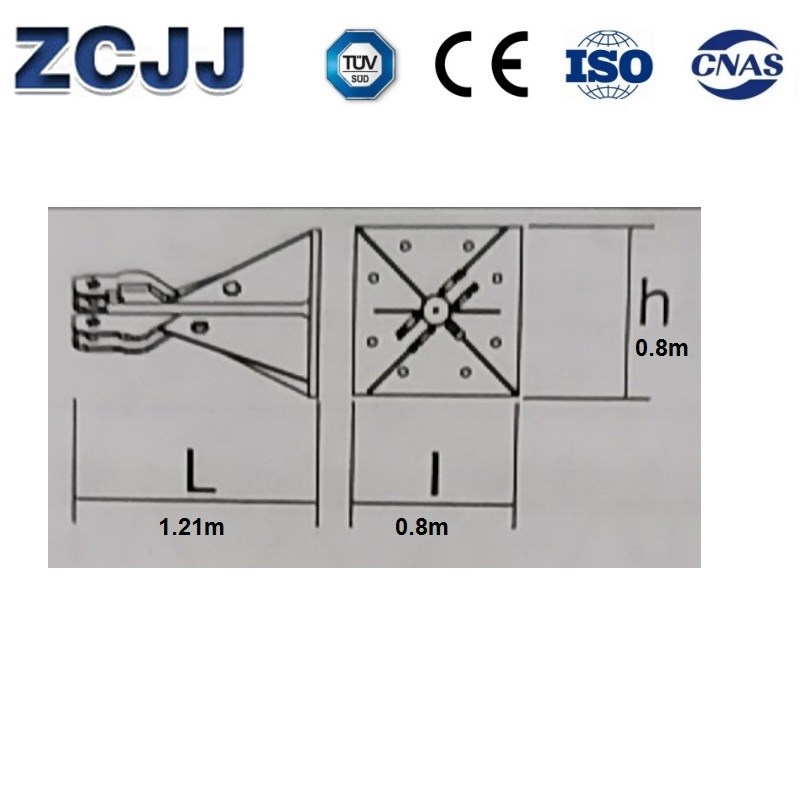

P80A Bases Fixing Angle Tower Crane

- ZCJJ

- China

- 5days

- 20sets

Najaf Tower crane

Jerusalem Tower crane, Tel Aviv Tower crane

Haifa Tower crane, Lixiong Lixian Tower crane

Amman Tower crane, Aqaba Tower crane, Ilbid Tower crane

Products Specification

Type , Model: Adaptor Mast From 1.6m L40 To 1.6 K40

Size: 2.9M

Use for : R87 Mast R87 Mast , 2.9x2.9x5.98m

Materials: Q345B

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

P80A Bases Fixing Angle Tower Crane

Tower Crane Knowledge sharing:

Special scheme for tower crane installation safety: installation requirements, preparation, jacking and operation

6. Provide special power supply for tower crane.

Preparation for tower crane installation

1. Prepare a 25-ton truck crane, common tools such as sleeper, wooden wedge, iron wire, steel wire rope, rope buckle, sledgehammer and monkey wrench.

2. Lay roads on the construction site and clear obstacles.

3. Check and accept the concrete foundation of tower crane first, the concrete strength shall reach 90% before the assembly of the whole machine, and the surface flatness of the concrete foundation shall not be greater than 1/500.

4. The tower crane shall be inspected by the crane driver as follows

(1) whether the steel structural members have cracking and de-welding.

(2) whether the wire rope is firm and reliable, whether it meets the requirements, and whether the rope binding head is reliable.

(3) whether the electrical components and components are normal.

P80A Bases Fixing Angle Tower Crane

(4) whether the guide wheel of the climbing mechanism rotates flexibly and whether the clearance with the tower crane meets the requirements.

(5) whether the jacking hydraulic device is normal.

(6) immersing and derusting the bolts and pins to be removed, and cleaning the dirt buried underground

(7) before installation, the rotating tower crane shall be overhauled and maintained seriously and the deformed parts shall be repaired in time

5. The crew shall level the foundation (four corners) of the tower crane, and its flatness shall be controlled within 1/1000.

Safety matters in tower crane installation

1. The installation and dismantling teams with professional qualifications shall operate.

2. All operating personnel must work with valid certificates, and those who have not obtained certificates shall not participate in the work.

3. All operators must follow the unified command of the general commander.

4.The general commander must follow the technical guidance of technical personnel and accept safety supervision.

P80A Bases Fixing Angle Tower Crane

5. Operators must wear safety helmet, climbing personnel must wear non-slip shoes, and safety belt must be fastened for dangerous parts.

6. All operating cranes must strictly abide by the safety technical operation rules.

7. Drinking is prohibited during installation.

8. When working from top to bottom, pay attention to the safe and reliable position of tools and parts to prevent falling and hurting people.

9. Concentrate on work and don't play jokes or slapstick at will.

10. The commanding personnel of the crane should be proficient in lifting performance of the crane, lifting weight of lifting objects and installation parts of components.

11. The command personnel shall unify the gesture signals with the crane driver.

12. the lifting height of large items more than two meters to tie the rope.

13. The hoisting rope must comply with the safety regulations, and the center of gravity of the hoisting components must be accurate and meet the requirements of the instruction.

14. the assembly of the general accessories and accessories must be in accordance with the provisions of all the above bolts and pins, to ensure the safety of use.

P80A Bases Fixing Angle Tower Crane

15. all the naked power lines in the operation area must be power cut, special guard.

16. Sufficient lighting must be provided for night operations.

17. Tower cranes are not allowed to be installed in heavy rain, strong wind, heavy snow and fog.