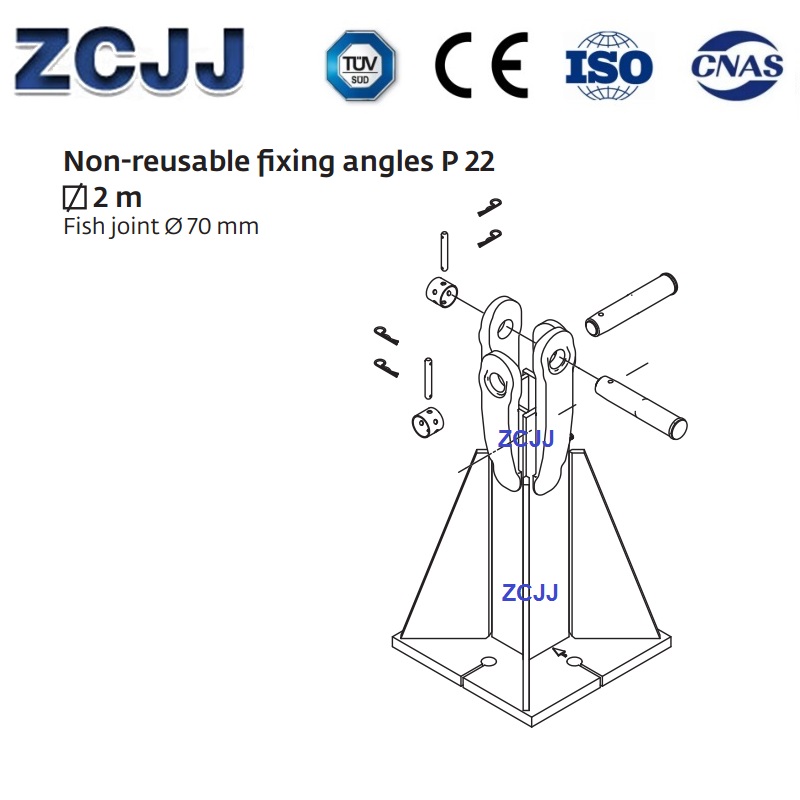

P22A Bases Fixing Angle Tower Crane

- ZCJJ

- China

- 5days

- 20sets

Tehran Tower crane, Isfahan Tower crane

Mashhad Tower crane, Shiraz Tower crane

Baghdad Tower crane, Basra Tower crane

Products Specification

Type , Model: P22A Bases Fixing Angle Tower Crane

Size: 2M

Use for : M619A Mast M619C Mast ,2.13X2.13X5.32

Materials: Q345B

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

P22A Bases Fixing Angle Tower Crane

Tower Crane Knowledge sharing:

Procedures and requirements for tower crane jacking: preparation, construction and tower attachment before operation

Procedures and requirements for tower crane jacking operation: preparation before tower crane jacking operation, tower crane jacking operation and tower body adhesion construction.

1. Preparation before tower crane jacking:

(1) align the standard section to the positive direction of the tower crane, clean the pin hole and pin shaft of the standard section, wipe oil, and conduct cleaning and refueling test on the hydraulic station.

(2) change the jacking hook, lower the trolley, hoist the first tower body, pay attention to the direction, load into the imported track, knock off the connecting pin shaft between the rotary table and the tower body, and turn to be in the braking state.

Jacking 15CM with a trolley to introduce balance, so that the balance point falls on the jacking beam, 15 minutes later to see whether the cylinder has no sliding phenomenon.

(3) in the jacking, the perpendicularity of the tower should be checked from two sides to avoid deviation in the distance between the tower and the building.

P22A Bases Fixing Angle Tower Crane

2. Tower crane jacking operation:

(1) after each part is normal, jacking is started. The pawls at both ends of the jacking beam are placed on the lugs of the tower body, and the top part of the tower is 0. 8 meters, set the ratchet on the beam on the tower lugs.

Take back the lifting beam of the oil cylinder and hang it on a pair of lugs, then lift up the tower head part, pull up the ratchet pawl of the cover frame, and then put on the ratchet of the cover frame about 1 meter after the oil is fully extended.

Then pull back the cylinder jacking beam to the upper pair of lugs, and then lift the tower head part, pull up the set frame pawl, when the cylinder is fully extended 1. 5 meters. At this time, please pay attention not to let the sleeve roller rush out of the tower body, and pull the top empty of the sleeve frame into the trolley to put the standard section in place.

Then, move the joystick to the descending position, and the standard section falls into the fishtail plate. Connect it with the pin shaft, and insert the safety pin to lock the standard section.

P22A Bases Fixing Angle Tower Crane

(2) hoisting the trolley into the standard section and hoisting it into the track. Remove the pin and repeat each (1) section until the desired height is reached. Connect the rotary table to the standard section with 8 pin shafts before operation.

(3) in the jacking process, a special person should open the hydraulic station to see the pawl and lug. No jacking is allowed if the wind speed is higher than level 4. In case of any abnormality in the hydraulic system during jacking, stop jacking immediately and pin the tower head on the tower body. If it exceeds the free height, bury the embedded parts in advance and attach.

3. tower body adhesion construction

(1) the tower crane is composed of a fixed attachment frame provided by the manufacturer, and the bracing rod and embedded parts shall be processed by the manufacturer on its own according to the drawings provided by the manufacturer.

(2) the project is expected to install a height of 70 meters, only one attachment, determined at a height of 30m.

P22A Bases Fixing Angle Tower Crane

(3) the vertical distance between the center of the tower and the building is 3. 5-5m depends on the actual situation.

(4) the horizontal error of the attached rod shall not exceed 200MM.