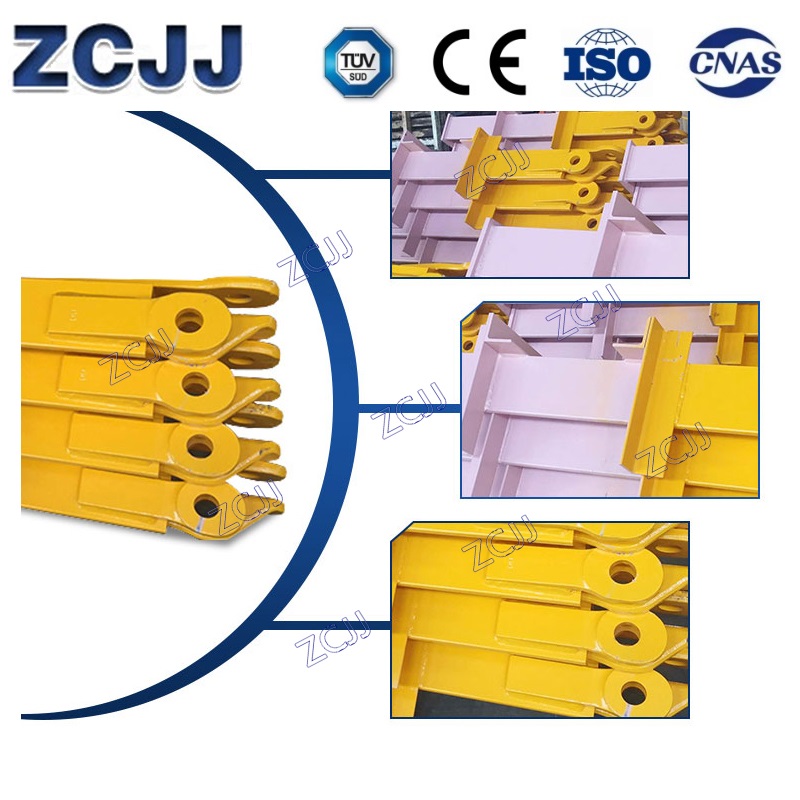

Bases Fixing Angles For L69B2 Mast

- ZCJJ

- China

- 5days

- 20sets

Colombia Tower Crane, Venezuela Tower Crane,tower crane operator job description

tower crane operator pay scale

tower crane operator bathroom

Products Specification

Type , Model: Bases Fixing Angles For L69B2 Mast

Size: 2M

Use for : L69 , L69B2 , L69B 2m L type mast, 2mx2mx3m

Materials: Q345B

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

Bases Fixing Angles For L69B2 Mast

Tower Crane Knowledge sharing:

Common problems and preventive measures in the operation of tower crane foundation and attached wall

Common problems and preventive measures in the operation of tower crane foundation and attached wall

1. Frequently asked questions

(1) the foundation ground endurance does not meet the requirements of the tower crane, do not use piling or filling pile measures and blind construction, resulting in the tower crane after the installation of the foundation settlement of large, vertical tilt over the norm and accident.

(2) foundation reinforcement shortage or concrete pouring is not dense and curing period to the concrete strength grade is not enough, and the installation of tower crane caused the accident.

(3) due to the needs of the engineering structure, the distance between the tower crane and the wall does not meet the requirements of the factory operation manual, the attachment rod is too long.

In the process of operation, there is no special plan and calculation, or the attachment rod is made of inferior material whose quality does not meet the national standard. During the welding operation, the welding seam is false welding, false welding and meat biting, which causes the welding seam to be torn or the rod to be broken.

Bases Fixing Angles For L69B2 Mast

2. Preventive measures and methods

Make the foundation strictly according to the instruction, and the ground endurance shall meet the basic requirements. Foundation reinforcement shall be strictly in accordance with the specification and shall not be increased or decreased at will.

At the time of pouring, the concrete grade shall not be lower than C35. After pouring, water storage and maintenance shall be carried out for pressure test blocks, settlement observation points shall be made, and installation of the whole machine shall be carried out after the strength of the test concrete reaches over 95%.

After installation, the vertical observation of the tower crane should be recorded regularly. The extra long wall should be designed by the factory or checked by the technical engineer of the unit and sent to the superior department for approval.

Qualified raw materials should be used for production. During the welding process, professional welders shall be sent to carry out the operation, and the welding shall be carried out in strict accordance with the requirements of the attached wall scheme.

In addition to the above requirements for mechanical construction operation, we also make the following Suggestions from the perspective of human management through long-term construction time:

Bases Fixing Angles For L69B2 Mast

<1>. Organize a professional team with high professional quality, strong technical force and rich operation experience, be proficient in the whole process of mechanical work, and master the professional technology of this type of work.

<2>. The field general commander should have a strong sense of responsibility and a high sense of safety, understand the professional technology of electromechanical integration, understand the construction principle,

Performance and application method of tower crane, be skilled in the process of disassembly and assembly, master the hoisting technology, and have a certain field command, organization ability and ability to deal with emergencies.

<3>. The professional team shall be composed of the person in charge with the title of engineer or above and the management team of mechanical, electrical engineer or mechanical and electrical technician and relevant professional personnel, equipped with the certificate of machine operator.

Installer, repairman, electrician and auxiliary worker, and issued the qualification certificate after training by relevant departments. All operators must hold a license.

Bases Fixing Angles For L69B2 Mast

<4>. Strictly implement the program approval and safety technical disclosure before the installation and disassembly of tower cranes.

<5>. Relevant departments and field safety management personnel shall adhere to the supervision and inspection during the dismantling and assembly of tower cranes.

In a word, tower crane, as an important large-scale mechanical equipment in construction site, is the fundamental premise and guarantee to give full play to its maximum function and safe operation.

All construction units must be people-oriented, sustainable development, strengthen the tower crane disassembly and installation management, to ensure that the safety of production is truly implemented, and resolutely put an end to the tower crane major malignant accidents.

Bases Fixing Angles For L69B2 Mast

Eliminate the tower crane in the process of disassembly and use of all hidden dangers, prevention, must be based on the safe and effective and reliable Angle to solve, not careless, this is the responsibility of the majority of equipment managers and operators.