Slewing Motor For Tower Crane

- ZCJJ

- China

- store

- 10sets

Finland Tower Crane rental, Sweden Tower Crane rental, Norway Tower Crane rental, Iceland Tower Crane rental, Denmark (Denmark) Tower Crane rental

Products Specification

Slewing Motor For Tower Crane

Tower Crane Slewing Motor

4F1 F2 B1 B2

85NM,145NM,120NM,95nm

RCV,OMD

Slewing Motor

Type Of Motor: Three- Phase Induction

Motor Model YTH112M-4

Engine Power: 4.4kw

Torque: N/M

Engine Rpm: 1400/1400/1700r/min

slewing motor for tower crane tower crane part tower crane, rcv slewing motor 95n/m-4f1 without brake

1. Brand :SCM,SYM,Yongmao.etc.

2. Type:185NM,145NM,1

selwing motor for tower crane tower crane part tower crane:

Type | Torque(N.M) | Current(A) | Electromagnetism torque(N.M) | Weathercock | Weight kg |

YTLEJ112M-55-4B1 | 55 | 24 | 35 | Yes | 85 |

YTLEJ112M-55-4B2 | 55 | 24 | no | No | 75 |

YTLEJ112M-65-4B1 | 65 | 26 | 35 | yes | 85 |

YTLEJ112M-65-4B2 | 65 | 26 | no | No | 75 |

YTLEJ112M-75-4F1 | 75 | 30 | 35 | Yes | 90 |

YTLEJ112M-75-4F2 | 75 | 30 | no | No | 80 |

YTLEJ112L-95-4F1 | 95 | 34 | 40 | Yes | 105 |

YTLEJ112L-95-4F2 | 95 | 34 | no | No | 95 |

YTLEJ112L-120-4F1 | 120 | 40 | 40 | Ye | 115 |

YTLEJ112L-120-4F2 | 120 | 40 | no | No | 105 |

YTLEJ132L-145-4F1 | 145 | 54 | 75 | yes | 145 |

YTLEJ132L-145-4F2 | 145 | 54 | no | No | 130 |

YTLEJ132L-185-4B1 | 185 | 68 | 75 | Yes | 155 |

YTLEJ132L-185-4B2 | 185 | 68 | no | No | 140 |

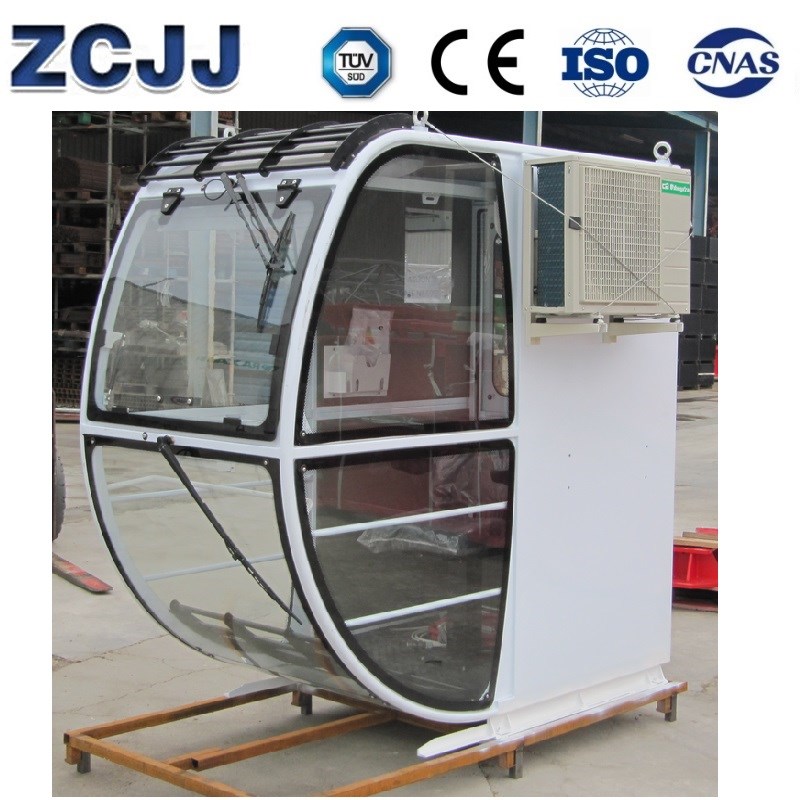

Our main products are tower crane parts, mast section. anchore frame, fixing angle, pin, bolt, various mech, assembly and spare parts, control box, resistance box and spare parts, drive room and spare parts, wire rope, pulley, cable etc. complete anti-parts

We can also supply any part of tower crane,such as hoisting mechanism,trolleynig mechanism,slewing mechanism and so on.

Slewing Motor For Tower Crane

Tower Crane Slewing Motor

4F1 F2 B1 B2

85NM,145NM,120NM,95nm

RCV,OMD

Tower Crane Knowledge sharing:

What is the reason for the shaking and noise when the tower ceiling rises?

The tower crane operator must have a solid tower crane technical knowledge, and carry out the tower crane maintenance and maintenance work on time. Only personnel and machinery can be put in place at the same time to ensure that the tower crane accident can be avoided.

Fault analysis and treatment method of jitter and noise when tower ceiling is lifted:

1. Causes of failure: The hydraulic system is mixed with air.

Solution: Exhaust.

1. Fault cause: oil pump suction.

Solution: Come on.

Tower Crane Slewing Motor

4F1 F2 B1 B2

85NM,145NM,120NM,95nm

RCV,OMD

1. Causes of failure: mechanical mechanism, hydraulic cylinder whole machine is too tight.

Solution: overhaul, replacement.

1. Causes of failure: internal leakage or oil seal damage in the system.

Solution: check or change oil seal.

1. Cause of failure: Hydraulic oil deteriorated.

Solution: exchange hydraulic fluid.

Analysis on the Causes of Common Fault of Tower Hang and the Corresponding Treatment

Tower crane is an important lifting equipment in the construction industry. There will be many failures in the use process. There are many reasons for this. In summary, it is mainly due to poor working conditions, delays in maintenance, illegal operations by operators, and natural wear and tear of parts and components.

In addition, accidents sometimes occur when the tower is suspended during commissioning.

When there is an anomaly in the tower crane, the operators such as the installation and unloading worker and the tower crane driver shall immediately stop the operation, report to the relevant department in a timely manner, and the full-time maintenance personnel shall come to repair, deal with the hidden dangers in a timely manner, and resume normal work.

The common faults of Tower hoists are generally divided into two categories: mechanical faults and electrical faults.

Tower Crane Slewing Motor

4F1 F2 B1 B2

85NM,145NM,120NM,95nm

RCV,OMD

Due to wear, deformation, fracture, clamping, poor lubrication, and incorrect relative position of mechanical parts, the mechanical system can not operate normally, which is collectively referred to as mechanical failure. Mechanical faults are generally obvious, intuitive, and easy to judge. In the tower lifting operation, it is more common.

Due to the failure of electrical lines, components, electrical equipment, and power supply systems, the power system can not operate normally, which is collectively referred to as electrical failure. There are relatively many electrical faults, some of which are more intuitive and easy to judge, and some of which are relatively hidden and difficult to judge.

Tower Crane Slewing Motor

4F1 F2 B1 B2

85NM,145NM,120NM,95nm

RCV,OMD