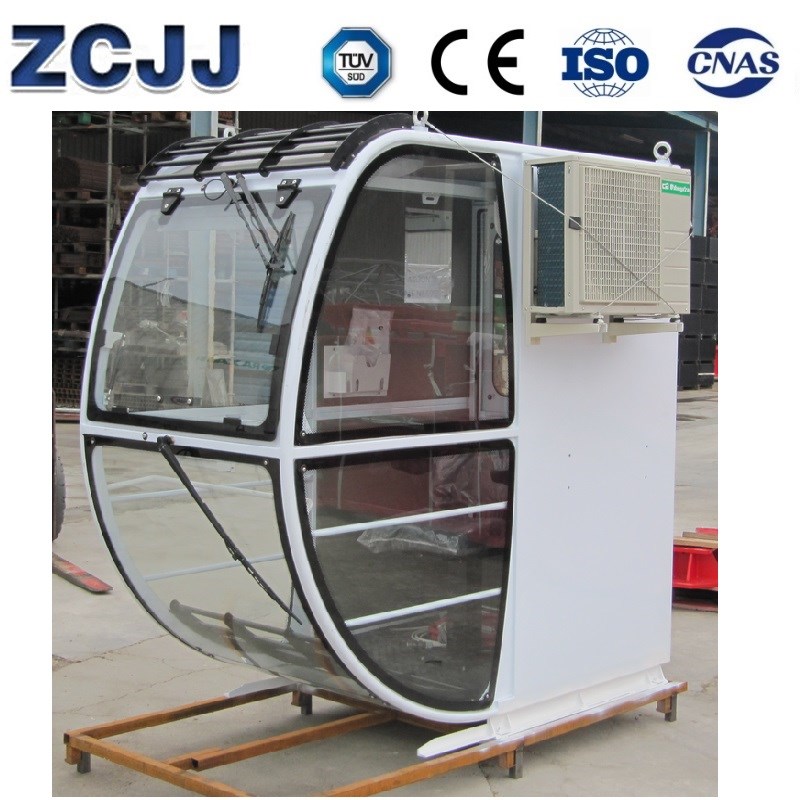

Jacking Telescopic Cage For Tower Crane

- ZCJJ

- China

- 10days

- 50pcs

San Pedro Tower crane service,

Bogota Tower crane service, Medellin Tower crane service,

Cali Tower crane service, Barranquilla Tower crane service,

Products Specification

tower crane jack telescopic cage ,1.2m , 1.6m ,2m

Jacking Telescopic Cage For Tower Crane ,1.2m , 1.6m ,2m

Tower Crane Jacking Cage ,1.2m , 1.6m ,2m

Tower Crane Climbing Cage ,1.2m , 1.6m ,2m

Size: For 1.2m , 1.6m , 2m L type mast section

The standard section is all processed by the overall sand blasting process. The surface is smoother and more beautiful. It is treated with anti-corrosion blasting. It uses the highest quality paint in the tower crane industry, with strong adhesion and longer durability.

All chord connections are all gas-shielded and welded. All the products are tested by weld inspection, x-ray and UT ultrasonic inspection. It is more secure.

tower crane jack telescopic cage ,1.2m , 1.6m ,2m

Jacking Telescopic Cage For Tower Crane ,1.2m , 1.6m ,2m

Tower Crane Jacking Cage ,1.2m , 1.6m ,2m

Tower Crane Climbing Cage ,1.2m , 1.6m ,2m

Tower Crane Knowledge sharing:

Rules for safe operation of tower crane: mechanical, personnel, environment, operation, etc..

This article mainly introduces the operation rules for the safe use of the tower crane, including the specific requirements for the tower crane machinery and equipment, the tower crane driver and other personnel management regulations, operating environment, and tower crane operation technology.

(1) The soil carrying capacity of the tower lifting base must be strictly in accordance with the original plant use regulations or meet: 8 to 12 T / M2 for medium-sized towers and 12 to 16 T / M2 for heavy towers.

(2) The rail or concrete foundation of the tower crane must be designed and checked before it can be used. Slope and drainage facilities should be built around the foundation and a certain safe distance should be maintained from the foundation pit.

tower crane jack telescopic cage ,1.2m , 1.6m ,2m

Jacking Telescopic Cage For Tower Crane ,1.2m , 1.6m ,2m

Tower Crane Jacking Cage ,1.2m , 1.6m ,2m

Tower Crane Climbing Cage ,1.2m , 1.6m ,2m

(3) The lifting shall be dismantled and installed by a specialized team that has obtained the qualification certificate issued by the competent administrative department for construction, and shall be supervised by technical and safety personnel in the presence of such personnel.

(4) The disassembly personnel shall wear safety and protective supplies, wear safety belts when working high, and be familiar with the disassembly process and operating procedures.

(5) After the tower crane is installed, it shall undergo technical inspection and adjustment of the whole machine, and it shall be delivered for use only after the whole machine has passed the inspection in phases. In the absence of load, the vertical deviation between the tower body and the ground must not exceed 4/1000.

tower crane jack telescopic cage ,1.2m , 1.6m ,2m

Jacking Telescopic Cage For Tower Crane ,1.2m , 1.6m ,2m

Tower Crane Jacking Cage ,1.2m , 1.6m ,2m

Tower Crane Climbing Cage ,1.2m , 1.6m ,2m

The motor and hydraulic parts of the tower crane shall be carried out in accordance with the relevant provisions concerning electric motors and hydraulic devices.

(6) No lifting, installation or disassembly shall be carried out when the wind reaches level 4 or above.

The connection of various parts of the hydraulic lifting system must be checked before lifting. It is strictly forbidden to turn the boom and other work when climbing.

(7) In the event of strong winds or heavy rain, heavy snow, heavy fog and other bad weather, the tower lifting should be stopped. When working after rain and snow or in rain and snow, you should first go through the test crane to ensure that the brake is sensitive and reliable before operating.

tower crane jack telescopic cage ,1.2m , 1.6m ,2m

Jacking Telescopic Cage For Tower Crane ,1.2m , 1.6m ,2m

Tower Crane Jacking Cage ,1.2m , 1.6m ,2m

Tower Crane Climbing Cage ,1.2m , 1.6m ,2m

(8) There shall be a reliable grounding device for the metal structure of the tower crane, the track and the metal housing of all electrical equipment, and no more than 4

Ω of ground resistance, and lightning protection shall be provided.

(9) The arrangement, spacing and wall distance of the poles of each attachment device shall be in accordance with the original regulations, and the design calculation book for the self-made poles shall be provided.

(10) Tower hoisting shall not be carried out near overhead transmission lines. If the conditions are limited to the site, safety and protection measures must be taken when operating along the line. The safety distance between the tower crane and overhead transmission wire should meet the regulations.

(11) Prior to operation, a comprehensive understanding of the surrounding environment, roads, overhead wires, buildings, and weight and distribution of components at the work site is required.

tower crane jack telescopic cage ,1.2m , 1.6m ,2m

Jacking Telescopic Cage For Tower Crane ,1.2m , 1.6m ,2m

Tower Crane Jacking Cage ,1.2m , 1.6m ,2m

Tower Crane Climbing Cage ,1.2m , 1.6m ,2m

(12) There shall be sufficient working space for the lifting of the tower. There shall be no obstacles in the lifting and landing of the heavy arm rod and the radius of rotation of the tower.

(13) The operator should make a sound before performing such actions as lifting, rolling, walking and lifting. The voltage of the check power supply should reach 380V, and its change range should not exceed +20 V, -10 V.

The start control switch before transmission should be in zero position. The power supply should be turned on and the metal structure part should be checked for no leakage.

(14) In the event of difficulties in the normal command of a tower hanging away from the ground in the control room, there may be two commanding personnel at high altitude and on the ground, or effective contact methods such as walkie-talkies may be used to command.

(15) Safety protection devices, such as barometer, walking limiter, moment limiter, hook height limiter and various stroke limiter switches, must be complete, sensitive and reliable, and must not be arbitrarily adjusted and removed. It is strictly forbidden to replace the control mechanism with a limiting device.

(16) The commander of the tower crane must be certified for duty and should work closely with the operator. Operators must also be certified for duty, and should strictly execute the signals of the command staff during the operation.

If the signal is unclear or wrong, the operator should refuse to perform it. If an accident is caused by an error in command, the commander shall be responsible.

(17) No person is allowed to stay, work or pass under the lifting arm or heavy object during the lifting operation of the tower. When lifting heavy objects, it is forbidden to pass over people. It is forbidden to carry people by tower.

tower crane jack telescopic cage ,1.2m , 1.6m ,2m

Jacking Telescopic Cage For Tower Crane ,1.2m , 1.6m ,2m

Tower Crane Jacking Cage ,1.2m , 1.6m ,2m

Tower Crane Climbing Cage ,1.2m , 1.6m ,2m

(18) Tower lifting machinery must carry out lifting operations in accordance with regulations, and must not overload or lift objects of unknown weight.

In special cases, when overloading is required, it must be checked, there are technical measures to ensure safety, and with the approval of the person in charge of the enterprise's technology, there must be a person in charge of the on-site supervision before lifting, but it must not exceed 10 % of the limit.

(29) The lifting and landing speed of heavy objects must be uniform, and it is forbidden to creep and brake suddenly.

The left and right rotation action should be stable, and no reverse action must be made before the rotation is stabilized. Non-gravity descending tower crane, no free drop is allowed.

(20) The minimum distance from the top of the tower hook device to the bottom of the car frame: 1000mm at the upper rotary rate of 2 times, and 700MM at the 4 times rate; The downward rotation is 800mm at 2 times. The rate of 4 times is 400mm, which should immediately stop lifting.

(21) During the operation, when the operator temporarily leaves the operating room, he must cut off the power and lock the rail clamp.

After the operation is completed, the tower crane should be parked in the middle of the track, the lifting arm should be turned to the downwind direction, and the rotary brake should be released.

The car and balance weight should be placed in a non-working state, and the hook should rise to 2 to 3M from the top of the lifting arm.

(22) It is strictly forbidden to hang heavy weights in the air for a long time. In case of sudden failure in operations, measures should be taken to land heavy objects in a safe place, and the motor should be turned off or the power supply cut off for maintenance.

In the event of a sudden power outage, all controllers should be immediately put to zero, the main power switch should be disconnected, and measures should be taken to safely reduce the weight to the ground.

(23) It is strictly forbidden to use a tower crane for lifting, sloping and lifting heavy objects laid or condensed on the ground. Concrete members or templates poured on site must be fully loose before they can be lifted.

(24) When lifting heavy objects, they should be tied smoothly and firmly, and must not pile or hang sporadic items on heavy objects. Sporadic materials and objects must be firmly tied with hanging cages or wire ropes before they can be lifted. Items marked with the location or marking shall be tied according to the marked position.

The angle between the tied wire rope and the object shall not be less than 300 °.