K4 56C CATALOGUE MANU

- Famous Global

- Global

- 5 to 50days

- as u need units

The Bahamas used Tower Crane, Cuba used Tower Crane, Jamaica used Tower Crane,

K4 56C CATALOGUE MANU

Collect the Catalogue and Manu connect with us please.

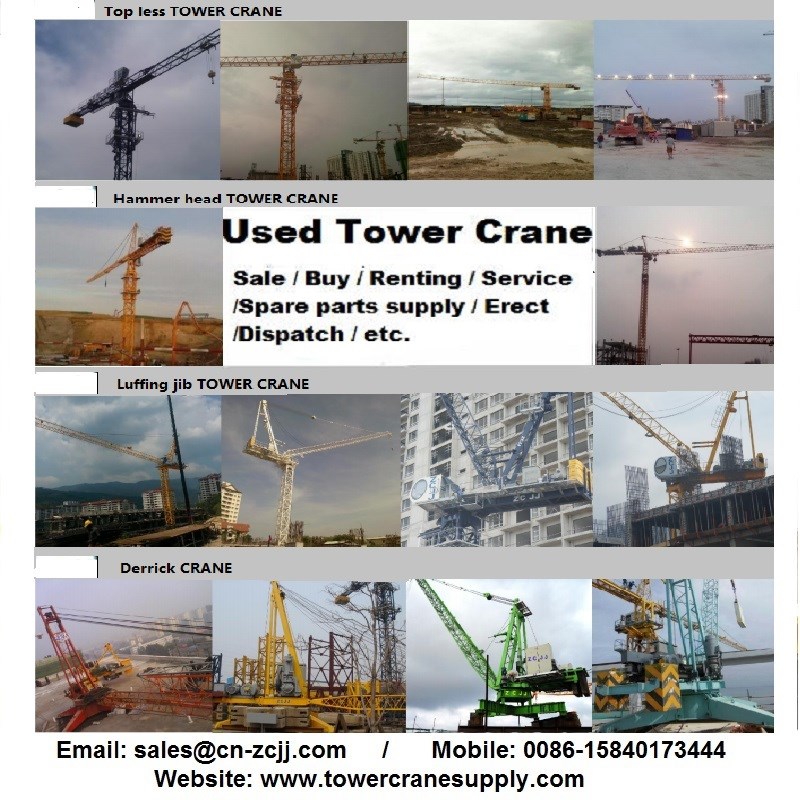

Series , Luffing jib Crane, Topkit tower crane, Hammer head tower crane, Topless tower crane, Flat top tower crane,

Model,

Jib length, m

Max load, Ton

Tip load, Ton

Type, Stationary , Inter climbing ,Travelling,

And other Famous brand, Model , Depend on the brand , Model Ability , Year , Height and etc u want.

We have large units store. From 6Ton to 20Ton. Store and Service all over the world.

Mean time , We supply all the Spare Parts U may need as follow,

Masts Section , Anchor Frame, Collar ,Tie , Fixing angle , Cabin, Hoist mech. Trolley mech. Luffing Mech. Slewing Mech. Pulley and etc.

K4 56C CATALOGUE MANU

Tower Crane Knowledge sharing:

tower crane installation steps of tower crane installation

8) on flat ground assembled good balance arm, and the lifting mechanism, distribution box, such as resistance box installed on the balance arm, connect the parts required for the wire, and then, the balance arm hung with the bearing pin shaft fixed edge to end, again raise balance arm into a perspective to the installation position of balance arm pull rod, installed balance arm pull rod, and then the crane unloading.

K4 56C CATALOGUE MANU

9) hoist the 0.6t tail weight onto the platform at the end of the balance arm.

10) on the ground, after checking the electrical equipment in the driver's cab, lift the driver's cab above the upper support, and then connect the driver's cab with the upper support with a pin shaft.

11) the installation sequence of lifting boom and lifting boom pull rod shall not be confused.

12) assemble the length of the boom and assemble them together with the corresponding pin shaft. Install the trolley and the hanging basket, and fix the trolley and the hanging basket at the root of the lifting boom.

Put the lifting boom on the 1m high support, make the car and the basket off the ground, install the car traction mechanism, all the pin shaft should be installed on the cotter pin, and open the cotter pin.

13) assemble the boom pull rod length, connect them with the pin shaft, and fix them on the corresponding bracket of the boom on the boom.

K4 56C CATALOGUE MANU

14) check whether the circuit on the lifting boom is perfect, and put on the trolley traction wire rope.

15) hoist the crane boom assembly smoothly with the truck crane. The handle horizontal position of the crane boom must be maintained in the lifting process, so that the crane boom can be smoothly installed on the hinge points of the crane boom with the upper support as the seat.

16) after the lifting boom is connected with the upper support, continue to lift the head of the lifting boom to slightly lift, and the lifting mechanism wire rope around the installation pulley on the top of the tower, and then start the winch to pull up the pull rod, which is connected to the pulling plate on the top of the tower with the pin shaft.

17) loosen the lifting mechanism wire rope, slowly lower the lifting boom, make the pull rod in the state of tension, and then loosen the lifting wire rope.

K4 56C CATALOGUE MANU

18) hoisting balance weight.

19) thread and wind the lifting wire rope, draw the lifting wire rope out from the drum, pass the guide pulley on the top of the tower, bypass the lifting weight limiter pulley on the lifting boom board and then lead it to the trolley pulley and the lifting hook pulley to be wound. Finally, secure the end of the rope to the arm.

20) drive the trolley to the root and turn the small storage rope drum with the pulley on the trolley to tighten the index rope as much as possible.

21) installation standard section

K4 56C CATALOGUE MANU

A. Rotate the lifting boom to the direction of the standard section of the tower body. If several standard sections are to be added, hoist the standard sections to be added one by one and arrange them directly below the lifting boom.

B. The length of the relaxing cable is slightly larger than the total climbing height, and the climbing frame and the lower support should be connected with 4 pins.

C. Hook the standard section with the imported trolley on the ground, then lift the standard section, and adjust the position of the trolley so that the upper center of gravity of the tower crane falls on the jacking position of the cylinder beam.

D. remove the four high-strength bolts between the tower body and the lower support.

E. Hang the hanging plate of jacking beam on the step of tower body, start the hydraulic system to make the piston rod all extend, shrink the piston rod slightly to make the climbing claw on the cover rest on the step of tower body, then, the oil cylinder all retract, make the jacking beam hang on the step of tower body again, all extend the oil cylinder again.

So three times, the tower above is just have space to pull the car into a tower body standard section, using imported cars on the introduction of beam rolling, lead to the tower above the standard section, on the standard section of the bolt connection hole shrink back to the oil cylinder to the top and bottom section.

when in contact with four M45 high strength bolt will be up and down the tower section connection, late out of the car, with hook hanging down the introduction of the car, hook live to want to add a standard section.

F. Tighten the four connecting bolts between the lower support and the tower body after adding the second section as described above.

G, the installation of the four poles on the bottom frame, so far, the tower crane is installed, the safety device is adjusted, can enter the state, if also add section, according to the above method.

22) upon completion of adding sections to the tower crane, the boom shall be rotated to different angles to check the tightening of high-strength bolts at each junction of the tower body.

After the tower crane is installed, the crane torque limiter, lifting weight limiter, amplitude limiter, lifting height limiter, braking adjustment, car braking adjustment and rotary brake adjustment must be adjusted prior to the work of the safety device. After the adjustment, the crane can be used