Hoist Panel Box For Tower Crane

- ZCJJ

- China

- store

- 10sets

The Bahamas Tower Crane rental, Cuba Tower Crane rental, Jamaica Tower Crane rental, Haiti Tower Crane rental, the Dominican Republic Tower Crane rental, Antigua and Barbuda Tower Crane rental, St. Kitts and Nevis Tower Crane rental,

Products Specification

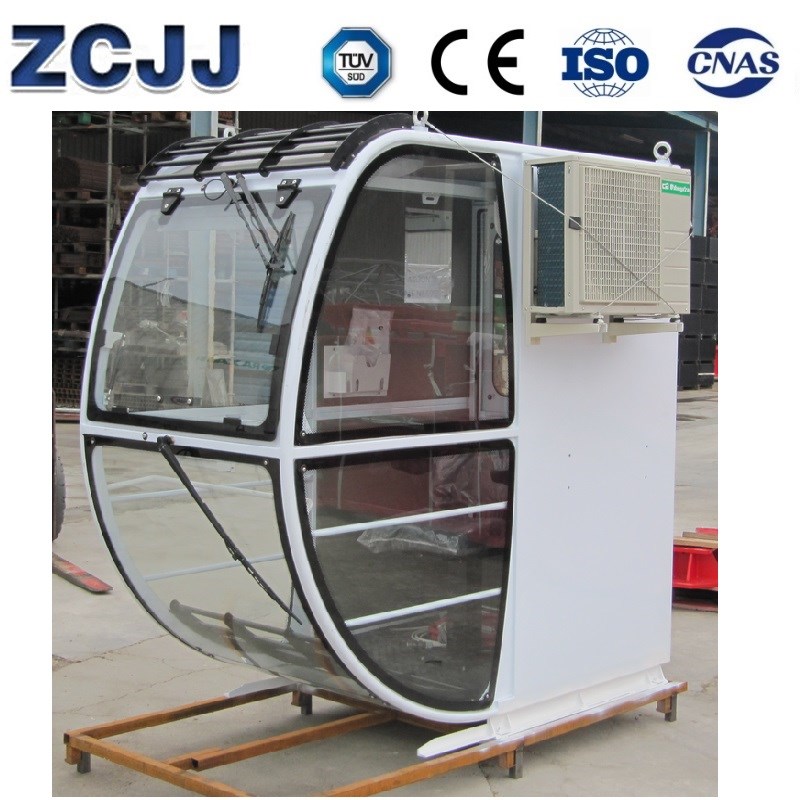

Hoist Panel Box For Tower Crane

Tower Crane Hoist Panel L Box rcs

Tower Crane Hoist Box

LVF Invertor

Tower Crane Electrical Control Panel Box

NAME | MODEL | POWER(HP) | LOAD(t) | SPEED ADJUSTMENT MODE |

NORMAL CONTROL | 45RCS | 45 | 8 | 5 Dual series motor speed |

55RCS | 55 | 10 | 5 Dual series motor speed | |

70RCS | 70 | 10-20 | 5 Dual series motor speed | |

PLC CONTROL | 45RCS | 45 | 8 | 5 Dual series motor speed |

55RCS | 55 | 10 | 5 Dual series motor speed | |

70RCS | 70 | 10-20 | 5 Dual series motor speed |

RCS Tower Crane Electrical Control Cabinet

RCS tower crane electrical control cabinet is a tower crane hoist electrical control system solution independently designed and developed by our company on the basis of advanced tower crane control technologies .It has such characteristics as high working rate,good speed regulation performance,smooth working ,high efficiency and so on.the system contains cabinets A,L and HF,cabinet A is responsible for providing power for each mechanism of the tower crane and controlling & protecting traveling mechanism;cabinet L takes charge of control and safety protection of hoisting mechanism; cabinet HF is in charge of control and protection of slewing mechanism and luffing mechanism. Temperature range:-20℃-+40℃humidity:lower than 85%RH(no moisture condensation)

Altitude:the altitude of installation location shall not be higher than 1000 m.power grid quality:the voltage fluctuation range shall not exceed ±10% of the rated voltage. power capacity shall be guaranteed fully.

Hoist Panel Box For Tower Crane

Tower Crane Hoist Panel L Box rcs

Tower Crane Hoist Box

LVF Invertor

Tower Crane Electrical Control Panel Box

Tower Crane Knowledge sharing:

The function, structure and working principle of lifting weight limiter

Tower crane is a large lifting equipment, installed with a limiter and other safety devices, can effectively reduce the incidence of tower crane accidents. In this paper, the function, structure and working principle of the weight limiter around the tower will be explained and analyzed. Some of the content was arranged on the network for the reference of the majority of the tower hanging industry. If you have any questions, we would like to discuss them together.

1. Act as a weight limiter:

When the lifting load exceeds the rated load, the lifting weight limiter can output the electrical signal, cut off the lifting control loop, and can issue an alarm to prevent the tower from overloading.

Hoist Panel Box For Tower Crane

Tower Crane Hoist Panel L Box rcs

Tower Crane Hoist Box

LVF Invertor

Tower Crane Electrical Control Panel Box

The existing national standard "Safety Regulations for Tower Cranes" stipulates that tower cranes should be equipped with weight limiters.

If a weight display device is installed, the numerical error should not exceed 5 % of the actual value. When the maximum rating of the starting weight is greater than the corresponding block and is less than 110 % of the rated value, the power supply in the ascending direction of the lifting mechanism shall be cut off, but it may be used as a motion in the descending direction.

2. Construction and operation of the lifting weight limiter:

At present, the most commonly used weight limiter is a force measuring ring type. It consists of a force measuring ring, a guide pulley, and a limit switch. It is characterized by compact size, good performance and easy adjustment. FO/23B, QT80 and other towers are generally used in various forms of this structure.

A section of the force measuring ring is fixed on the support of the tower crane mechanism, and the other end is fixed on the guide pulley.

Working principle: tower lifting heavy lifting, pulley by the joint action of steel wire rope, the force passed to the measuring ring, measuring the deformation of the ring and load into a certain proportion.

Hoist Panel Box For Tower Crane

Tower Crane Hoist Panel L Box rcs

Tower Crane Hoist Box

LVF Invertor

Tower Crane Electrical Control Panel Box

Depending on the lifting load, the pulley will also have different force sizes. The shell of the measuring ring is deformed with the force, and the metal plate in the measuring ring is fixed with the shell of the measuring ring, and it extends with the deformation of the shell.

At this time, according to the load situation, the adjustment bolt fixed on the metal strip is adjusted. And the limit switch distance, When the load exceeds the rated lifting weight, the limited-position switch is moved so as to cut off the power supply of the lifting mechanism and achieve the purpose of limiting the lifting weight overload.

Can produce a variety of tower crane model products, tower crane equipment, accessories, JZ, JS series concrete mixer, PLD series batching machine, WJ80, WJ60 material hoist and other dozens of construction machinery products.

Hoist Panel Box For Tower Crane

Tower Crane Hoist Panel L Box rcs

Tower Crane Hoist Box

LVF Invertor

Tower Crane Electrical Control Panel Box

The time interval, maintenance steps and maintenance requirements of the tower crane overhaul are summarized below.

[After a long period of operation, the tower crane will undergo major repairs. The maintenance steps and maintenance requirements of the tower crane will be strictly in accordance with the regulations.

According to the overhaul of the tower crane products of the factory, the time interval, maintenance steps and maintenance requirements of the tower crane overhaul are summarized as follows.

The maximum repair interval for tower cranes should not exceed 15,000 hours. The maintenance steps and maintenance requirements are as follows:

1. All detachable parts of the tower crane shall be removed, cleaned, repaired or replaced(unless the manufacturer has special requirements)

2. Derust, paint.

3. Lube oil should be replaced

4. All motors shall be disassembled, disassembled and repaired.

5. The instrument used on the tower shall be repaired, inspected or replaced in accordance with the relevant regulations.

6. Replace aging wires and damaged electrical components.

7. Check the cable or puller of the arm frame.

8. When the overhaul is delivered, the tower crane shall achieve the working performance of the product when it is delivered, and shall have supervision and inspection certificate.

Hoist Panel Box For Tower Crane

Tower Crane Hoist Panel L Box rcs

Tower Crane Hoist Box

LVF Invertor

Tower Crane Electrical Control Panel Box