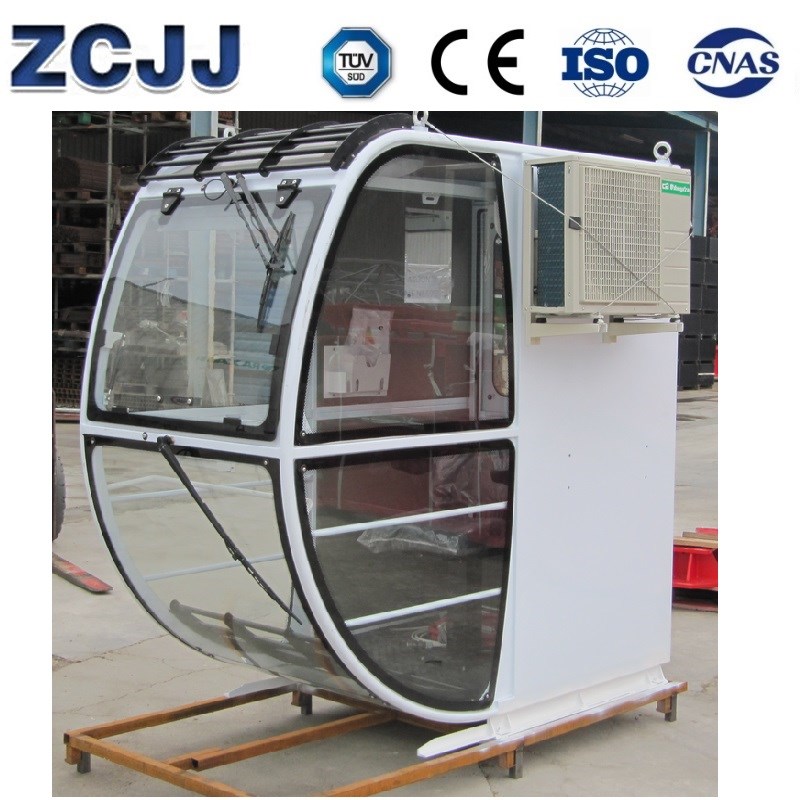

Cab Operator Chair For Tower Crane

- ZCJJ

- China

- store

- 10sets

Guatemala Tower Crane Spare parts, Belize Tower Crane Spare parts, El Salvador Tower Crane Spare parts, Honduras Tower Crane Spare parts, Nicaragua Tower Crane Spare parts, Costa Rica Tower Crane Spare parts , Panama Tower Crane Spare parts

Products Specification

Cab Operator Chair For Tower Crane

TOWER CRANE Cab Operator Chair

Cab Operator Chair For Tower Crane

TOWER CRANE Cab Operator Chair

Tower Crane Knowledge sharing:

What is a moment limiter? Analysis on the Role of the moment limiter for tower crane installation

Many of the reasons for the collapse of the tower crane were caused by overload. The reason for the overload was due to the fact that the weight of the weight exceeded the regulations,

Second, the horizontal distance of the weight exceeded the operating radius. After the installation of the torque limiter, when the weight is overweight or the operating radius is too large and the lead moment exceeds the technical performance of the tower crane, the lifting or changing power source is automatically cut off and an alarm signal is issued to prevent accidents.

Therefore, it is very important to install the moment limiter for the tower crane.

At present, there are two types of torque limiters: one is electronic and the other is mechanical.

Cab Operator Chair For Tower Crane

TOWER CRANE Cab Operator Chair

Electronic type: The torque, operating radius, and weight data can be read at the same time on the display. When approaching the allowable moment of the tower crane, there is an early warning signal and convenient to use, but it is affected by the operating conditions, the reliability is poor, and it is easy to damage and inconvenient to repair.

Mechanical type: no display device and no early warning signal, but the work is reliable, more suitable for on-site construction conditions, the structure is simple and the damage rate is low.

The respective characteristics of electronic and mechanical types

The moment limiter must be adjusted when the tower crane is reassembled at the conversion site, the ratio of times is changed, and the length of the lifting arm is changed.

The electronic overload alarm point must also be re-calibrated with the actual operating radius and actual weight test crane. When choosing a mechanical torque limiter for a tower crane with variable amplitude, it must be adapted to the tower crane(the same type of factory should be selected).

After each change in amplitude, the torque-varying tower crane equipped with a mechanical torque limiter must promptly adjust the tonnage of the overload limit and adjust it according to the allowable load of the operating radius.

Cab Operator Chair For Tower Crane

TOWER CRANE Cab Operator Chair

Torque limiter test:

During the security inspection, if the reliability of the moment limiter is unconditionally tested, the test operation record performed after the installation of the machine can be checked to confirm that the test results of the torque limit at that time meet the requirements, and the

comprehensive accuracy of the moment limiter system is satisfied. ± 5 % regulations.

Knowledge of requirements, inspection, working environment, repair and maintenance of tower crane operators

In tower crane production and has advanced tower crane technology and management experience. In this paper, the safety management of tower crane: operator requirements, inspection, working environment, maintenance and maintenance knowledge, etc., the paper briefly discussed with the majority of tower crane practitioners.

The tower crane operator requires:

1, each tower crane mechanical operator, not only has the tower lifting technology, but also has the normal maintenance technology for the tower crane. In other words, both tower maintenance and maintenance.

2, mechanics personnel must be licensed to take office, familiar with the maintenance of machinery and safety operating procedures, unrelated personnel must not climb the tower without permission.

Cab Operator Chair For Tower Crane

TOWER CRANE Cab Operator Chair

The operation of the tower crane must implement the three-top system, and the driver's operation must be strictly executed according to the operation rules of the tower machine. When handling electrical faults, two or more maintenance personnel are required.

4. the driver should be highly focused on tower crane repair and maintenance, such as to avoid the collision between the tower and the building around the tower.

Tower lifting routine inspection:

1. every day before commuting to and from work must carry out the most basic inspection and maintenance of the tower crane, and carefully do a good job of maintenance records, to ensure that the normal operation of the tower crane is the responsibility of each tower crane operator.

2. once a week to carry out minor maintenance and repair of the tower crane, and do a good job of normal operation records.

3. once a month to repair and maintain the tower, and do a good repair record, record the tower hanging before maintenance and after maintenance work status. Operation and maintenance of the tower.

Tower Working Environment:

1. the normal operating temperature of the tower is -20 ~ +40

°C, and the wind speed is less than 13m/s.

When working at night, in addition to the lighting of the tower itself, the construction site should have sufficient lighting equipment.

Tower Hang Maintenance and Maintenance Knowledge:

1, tower lifting maintenance and maintenance, when the tower machine every time the installation and use of the transfer field must be carried out empty loading, static loading experiments, dynamic loading experiments. The static load is 125 % of the rated load, and the dynamic load is 110 % of the rated load.

2) Tower machines shall be constantly inspected, maintained and maintained, transmission parts shall be adequately lubricated, vulnerable parts shall be constantly inspected, repaired or replaced, and connection bolts, especially those parts that are constantly vibrating, shall be checked for looseness. If loose must be tightened in time.

3. check and adjust the clearance between Zhidongwa and the brake wheel to ensure that the brake is sensitive and reliable, its gap between 0.5 and 1mm, and there should be no oil and other dirt on the friction surface.

4. the maintenance and maintenance of wire rope strictly in accordance with the provisions of GB5144-85, found that there are more than the relevant regulations, must be replaced immediately.

5. the structure of the tower machine, welds and related components, whether there is any damage, deformation, loosening, corrosion, cracks, if any problems should be repaired in a timely manner.

Cab Operator Chair For Tower Crane

TOWER CRANE Cab Operator Chair

6. tower maintenance and maintenance, the most important is the maintenance of various electrical lines.